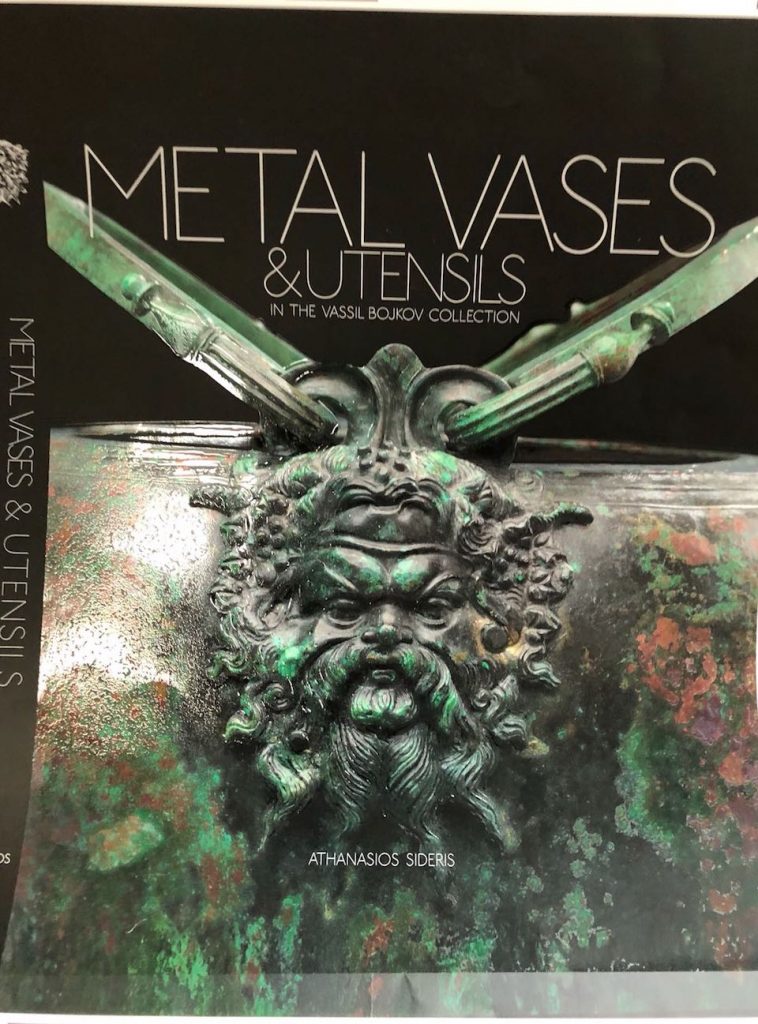

Relief printing

Screen printing provides higher relief than other printing technologies. However, you might not know that the relief can be regulated according to your preferences by changing the mesh, screen and inks. Relief printing makes your products more intriguing by enhancing certain key elements. Relief UV varnishing is a great example of that.

Special effects

Special effects are finishing options that make your products more memorable and exciting. They include but are not limited to: printing scratch off ink, which is used in various games, lottery tickets, promotional activities; phosphorescent inks that glow in the dark; thermochromic inks that appear or disappear at certain temperatures; metallic, pearlescent, fluorescent, glitter inks and many more. All of these can help you make your products unforgettable.

Highest stability of colors according to the Blue Wool Scale

The Blue Wool Scale is a scale that measures and calibrates the lightfastness of inks. You use two samples – one is put in the dark and the other is exposed to sunlight for about 3 months. Eventually, it is measured how much the sample has faded compared to the original color. The scale is between 0 and 8 where 0 is associated with extremely poor color lightfastness and 8 means that there is not any difference with the original color. The inks used in screen printing have lightfastness of 6-7 which is less than this of automobile varnish paints, but highest in comparison to the other inks.

Highest resistance against scratches

The thicker deposit on the substrate and the structure of the inks lead to higher resistance against all types of physical actions like scrubbing, folding and scratching. This preserves your products, making them last longer & look “just as new”.

Leave A Comment

You must be logged in to post a comment.