As promised…reasons 1 to 4 explained in more detail below:

Overprinting

Overprinting is a process that allows improving the production and broadening the spectrum of effects. Furthermore, it gives you the opportunity to correct errors and add missing elements. You can overprint all types of materials, laminated products and even products that are already assembled. Everyone makes mistakes, so sometimes you can forget to include a certain element, text or image. In such cases you can save your production through screen printing. We’ve overprinted missing elements on various finished products such as books, paper bags, calendars, etc.

Printing light colors on dark surfaces

Screen printing of light colors on dark surfaces not only does not ruin the colors, but leaves them dense and opaque. What makes screen printing different is that it allows you to print on any dark surfaces such as toned substrates, colorful materials, special papers, cardboards, etc.

Toning

Toning is the process of altering the color of a substrate. Screen printing leaves a thicker ink deposit on the substrate, which combined with the density of the inks, leads to an extremely even & opaque background. Other printing technologies also allow toning but the result doesn’t have the same coverage and all types of effects/defects of the substrate remain visible.

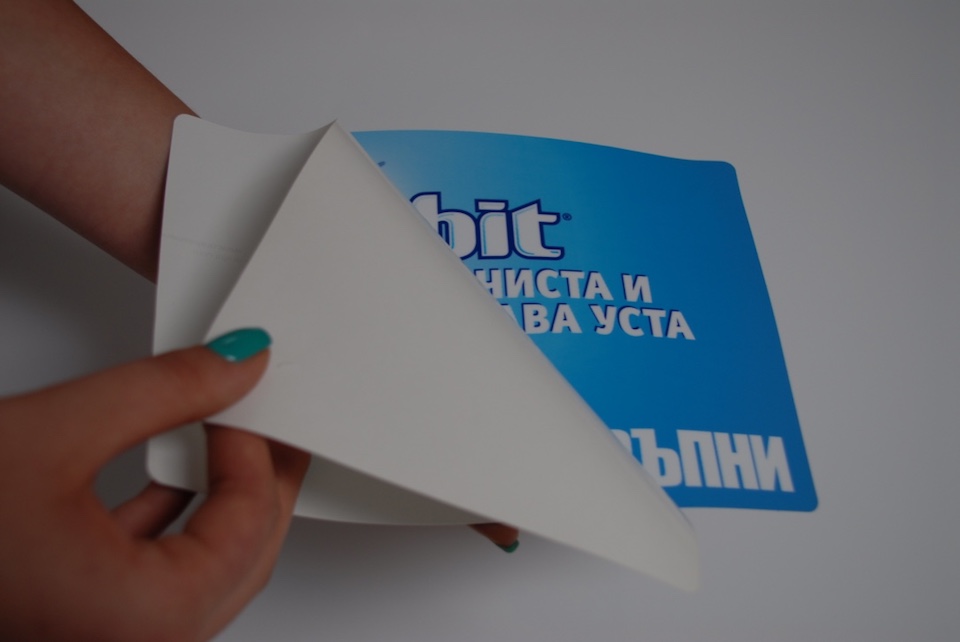

Opaque white

Opaque white

There is no other technology that can achieve such density of colors, especially when it comes to the so problematic white. As mentioned earlier, the combination of screen printing and the inks leads to perfect sealing and absolute opacity. This is extremely valuable in the production of push’n’pull stickers, window decorations and all kinds of products that require opacity and different appearance from different angles.

Leave A Comment

You must be logged in to post a comment.