UV Varnishing

Varnishing is the process of placing an additional layer of UV varnish to improve the quality and appearance of the products.

UV Varnish

UV coating is printing a layer of UV varnish on top of the printed sheet. The UV varnish is of extremely high quality and improves the quality of the product. The printed layer doesn’t only serve as protection against exterior influences but also betters the look of the product – it enhances the colours and gives a luxurious touch. You can choose between gloss or matte UV varnish.

Spot UV Varnish

Printing matte or gloss UV varnish on selected zones to emphasise particular elements.

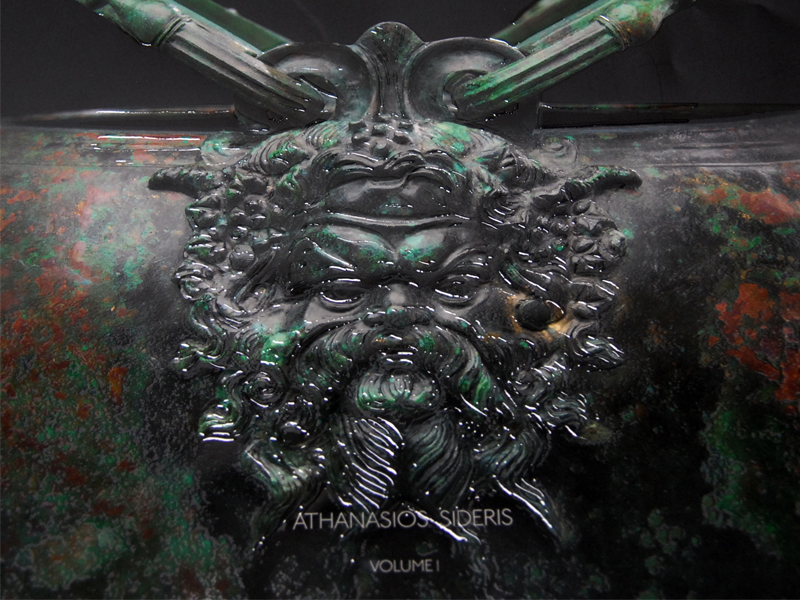

Relief Varnish

A specialised UV varnish that provides relief to the coated elements and creates an extremeply dynamic image. Suitable for printing the Braille alphabet.

Structural Varnish

Structural varnish allows printing images that mock up various forms and textures through layering standard or relief UV varnish. The result is not only visible but also tactile.

Microrelief Varnish

Microrelief varnish is a finer version of structural varnish. The printed outlines are extremely fine and reflect light in a different manner from every angle. That gives the products an unforgettable finish and you can even feel the fine fibers of the microrelief varnish that resemble the ones on banknotes.

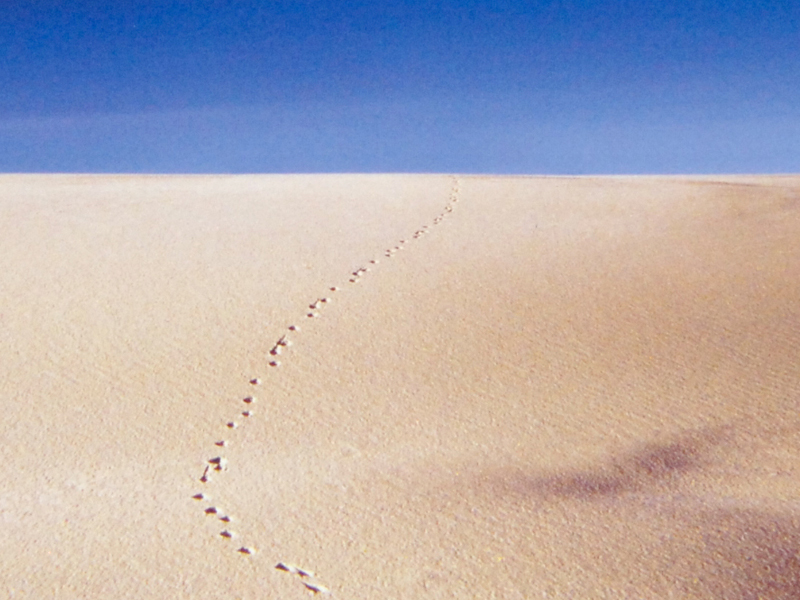

Abrasive Varnish

Printing abrasive varnish turns the relevant elements rough. That technique brings the image to live and teleports you to your dream destination. It is most commonly used to represent sand touch, rocks or road pavements.

Blister Varnish

It is widely used in creating packaging. Blister varnish is a coating that serves as glue when heated.

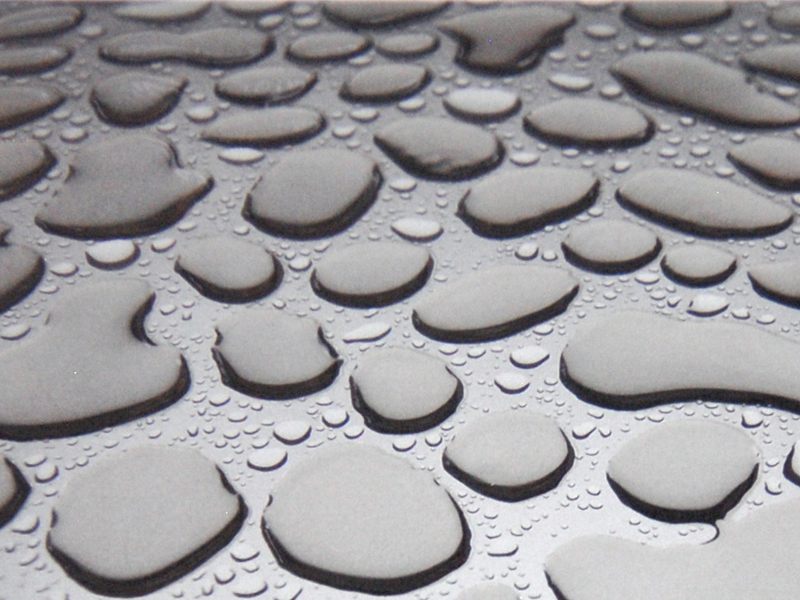

Drip-off

Drip-off varnish, aka hybrid varnish in offset printing, allows combining both matte and gloss UV varnish in one print. As a result some elements are coated with gloss varnish but the background is varnished with matte particles. Such prints are very interesting in terms of looks and texture.

Scented Varnish

It provides your products with the required aroma. The scented coating is actually a UV varnish containing scented oil microcapsules that release the relevant fragrance when touched or rubbed

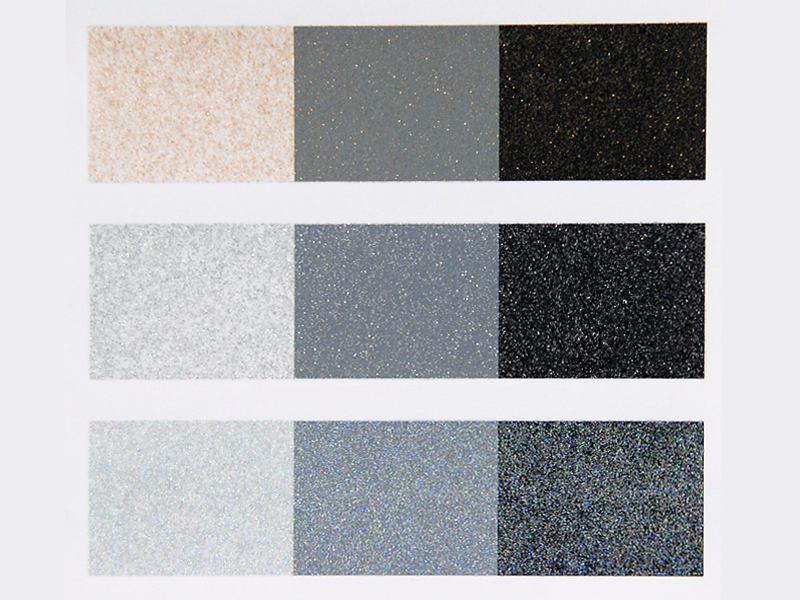

Glitter

If you would like to give your products an additional touch of glam, glitter is the way to go. The glitter pigment can be mixed in various ways depending on your preferences. There are three types of pigments – gold, silver, hologramic. Each of them has different brightness and reflects light in a different way. Other elements of the product (such as media it is printed on) could also affect the final results.